Description of theRef.ProcessingType O 15 x 5.5iCuttingType O 35 x 7.5iiCutting - PunchingType O 35 x 15iiiCutting - PunchingType G 32 x 15ivCuttingType C 30 x 15vCutting

Bending tool for efficient and precise bending of copper rods. Suitable for widths of 20-120mm with integrated protractor and blocking function to bend the same angle several times.

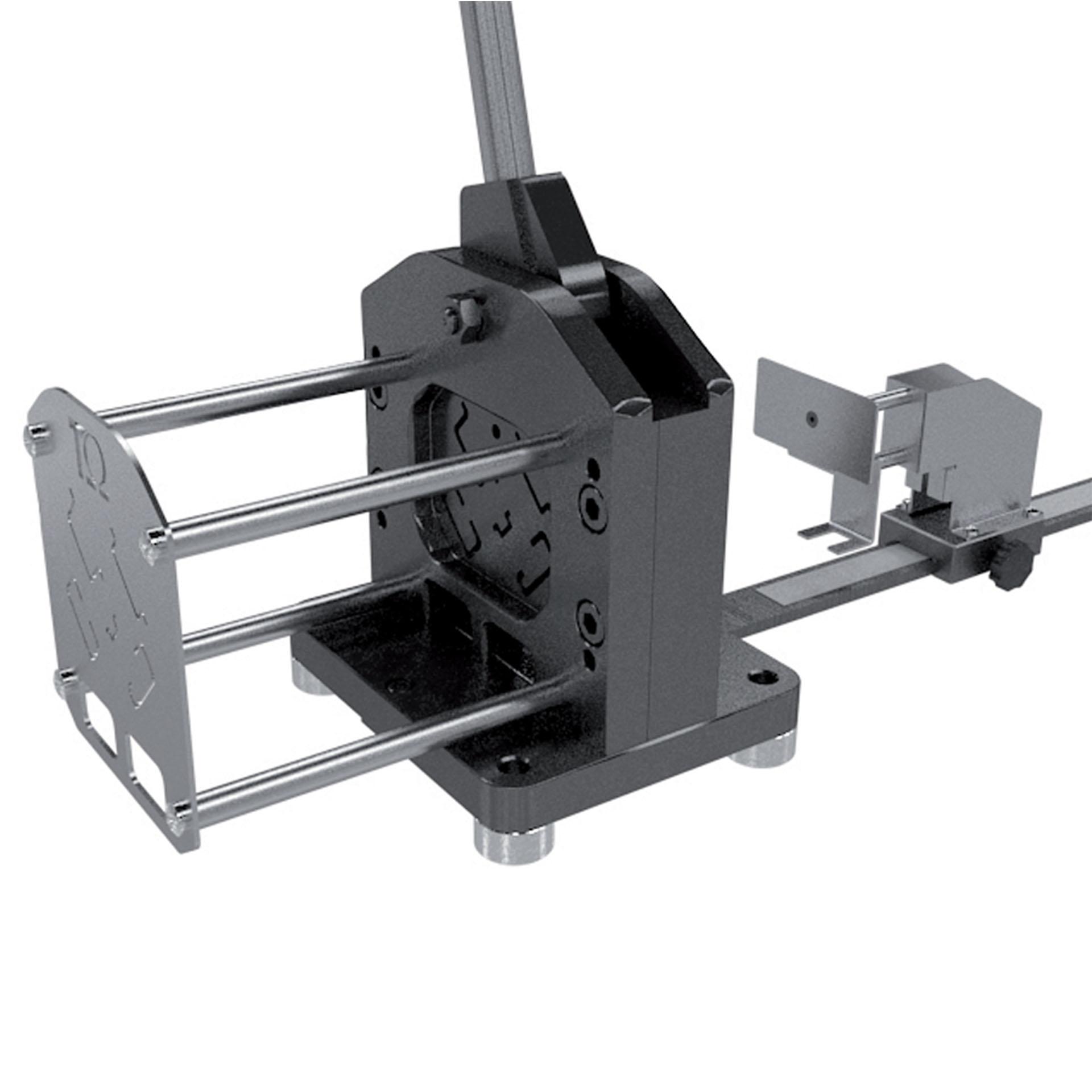

Jig for accurately drilling the holes for screwing the copper rod. Suitable for widths of 20-120mm with hole diameters of 6.5mm, 8.5mm, 10.5mm and 12.5mm.

Crimping force: 60 kN Application range: 10 to 240 mm² Application for: HR N, HRS N tubular cable lug, HSV butt connector, A series tubular cable lug, L M butt connector Battery: 18.0 V Metabo, CAS Smart Crimp: Adjustment of the crimping force depending on the cable lug size to avoid over-crimping / under-crimping, to save energy and reduce wear Housing: Steel housing with self-lubricating steel gearbox Safety: Double-click to start crimping Intelligent technology to notify the operator in the event of incomplete crimping Display: Clear and simple display Design: Slim design of the upper head to facilitate the positioning of small cable lugs Documentation: crimping cycles are documented in the device (data can be read out via USB cable and processed by software)

Contents of delivery: B600CND tool; MH25-60C press insert; MH35-60C press insert; MH50-60C press insert; MH70-60C press insert; MH95-60C press insert; MH120-60C press insert; MH150-60C press insert; MH185-60C press insert; MH240-60C press insert; Charger; 2x 18V Metabo battery; USB cable; Carrying strap; Case; Operating instructions; The B600CND from Cembre is the first of a new generation of portable cordless tools characterised by a "bi-linear" design.It is equipped with an intelligent automatic return at the end of the cycle (Smart Release). The B600CND is suitable for crimping cable lugs and connectors up to 300 mm². A new 18V - 2.0 Ah high-performance Li-Ion battery enables you to work independently for longer. The tool is also equipped with an overpressure sensor and a safety valve: The sensor guarantees greater repeatability of the maximum pressure, while the valve, on the other hand, provides important protection for the user. The EPS guarantees precision, checks the current pressure value and informs the user of possible errors (EPS). Various parameters can be shown on the OLED display: - Pressure and force of the work cycle, to check correct execution of the crimping - Battery status, - General data on operation, number of work cycles performed and possible until the next recommended maintenance. A new design, lower weight and ideal centre of gravity ensure more comfortable handling during use. While the plastic half-shells made of two different materials, with their robust structural elements, guarantee appropriate mechanical protection under all operating conditions, their rubber inserts ensure greater safety and more comfortable handling. Low-noise operation, LED illumination of the working area and minimal vibration make the tool even more comfortable to use. The operating parameters of the completed work cycles (max. 200,000) are saved on the integrated memory card and can be transferred to a computer via a USB interface (SMARTOOL Technology). Ambient temperature: -15 to +50 ° C

The B-TC320NDF belongs to the new generation of portable cordless tools, characterised by a "bi-linear" design. The B-TC320NDF hydraulic cordless cutting tool with double-piston hydraulics has been specially developed for cutting copper, aluminium and telephone cables up to a maximum diameter of 32 mm. The cutting blades are made from a high-quality material that guarantees a long service life. The open head makes it easier to work in hard-to-reach places. Handling is very easy thanks to the 180° rotatable head. The hydraulic cordless cutter is equipped with a pressure relief valve to prevent overloading. A pressure release button ensures easy handling of the tool at all times. The battery is equipped with an LED display. By pressing the button on the battery, the remaining battery life is displayed. Noise and vibrations are very low during operation. Ambient temperature: -15 to +50 °C.

B-FL750ND belongs to the new generation of portable cordless tools, characterised by a "bi-linear" design. It is a hydraulic battery tool with double piston hydraulics for punching stainless steel, steel, glass fibre reinforced plastic, up to a material thickness of max. 3.5 mm. Noise and vibrations are very low during the punching process. At the start of the punching process, the tool generates a high force and then automatically switches to a slower working stroke at the start of the punching process. The punching head can be rotated through 360° and swivelled through 180°. The battery is equipped with an LED display. By pressing the button on the battery, the remaining battery life is displayed. The housing is ergonomically shaped for optimum working conditions. Ambient temperature: -15 to +50° C